Life science instruments present unique challenges

to suppliers of light-generation equipment:

Inexpensive,

high-intensity, uniform, monochromatic

light across a broad UV-VIS-IR spectrum is

required. Competition is keen within today’s $50–60

billion biophotonics marketplace1 to find commercial

lighting solutions that provide for all of these

requirements with a low-cost and durable emitter

that, ideally, could be miniaturized for portability.

Today’s commercial light sources include lamps,

lasers, and light-emitting diodes (LEDs). Arc and

tungsten lamps offer white light for a broad range

of uses. Lasers are the brightest and most spectrally

pure light sources, while LEDs offer by far the lowest-cost

light source option. Manufacturers of lighting

equipment have engineered solutions for multicolor

emissions utilizing lamps based on these technologies:

externally filtered lamps, bundled lasers, and

LED arrays. However, no competitive technology

employing these techniques provides a cost-effective

solution for the range of bioanalytical tools used in

today’s life science marketplace.

While each of these solutions has advantages, some

fundamental limitations are not addressed. Lamps

are notorious for their spectral drift and short lifetimes.

Lasers are restricted to particular wavelengths

and require significant safety precautions. LEDs have

limited spectral outputs and although considered an

inexpensive lighting solution, when bundled to generate

adequate intensity, costs associated with their

implementation soar. Currently available commercial

light sources compromise throughput and sensitivity,

lead to frequent instrument calibration, and generate

high cost of ownership. Consequently, instrument

performance is constrained and overly priced.

Based on well-understood light pipe architectures, a

light engine solution based on luminescent pipes has

been developed (Lumencor, Inc., Beaverton, OR) to

fill a void and satisfy the growing bioanalysis market.

Lumencor light engines (patents pending) utilize

solid-state luminescent materials, excitation sources,

and optimized light management techniques. In order

to best appreciate the relative merits of these lighting

tools, a more detailed consideration of the competitive

technical and business landscape follows.

Lamps

The primary light sources for PCR and Sanger

sequencing instruments are tungsten halogen lamps,

arc lamps, and lasers. The tungsten halogen lamp is

a mature product, having been optimized for display

and lighting applications. Improvements in its low

light-collection efficiency or mitigation of high thermal

emissions are unlikely. Durability and stability

issues are also inherent and difficult to resolve. Its

cost could come down, but only if driven by volume

applications. This white light source with a width

of over 1000 nm must be heavily filtered to create

the 10–30 nm bands required in many bioanalytical

instruments. As such, light output to the sample

volume is quite low, on the order of a few hundred

mW/cm2, which relegates use of this lamp to low-throughput

applications.

To overcome this limitation, instrument designs

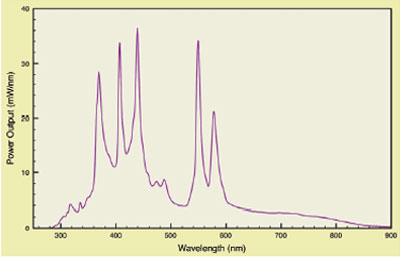

employ arc lamps. Figure 1 shows the typical emission

curve of a metal halide arc lamp.2 These high-power

lamps generate large light levels. They also

generate very broad white light that must be heavily

filtered. Additionally, they create significant heat

loads that must be managed to avoid compromising

bioanalytical chemistry and instrument performance.

Power instability due to the changing arc over its

lifetime is a notorious problem. Arc lamps have been

significantly improved due to proliferation in newer

microdisplay-based projection televisions and business

projectors. However, the availability of low-cost LEDs

has diffused efforts to improve the arc lamp. Typically

arc lamps, with their associated filters and spectral

wheels, mirrors, controllers, and shutters, add as much

as $10,000 to the cost of a $3000–$5000 bulb.

Figure 1 - Typical metal halide arc lamp spectrum.

Lasers

A common alternative to broadband lamps is the

laser. One of the most frequently employed in bioanalyses

is the air-cooled argon ion laser. A typical

laser, for capillary-based sequencing, for example,

provides 10–25 mW in a collimated, multiline beam.

However, the laser color balance is inherently unstable;

the power output of individual wavelengths varies

over time and from product to product. Additionally,

lasers are limited in the number of wavelengths

available, and their speckle patterns are an obstacle

for many applications in which field uniformity is

important. They are nonlinear devices built to be run

in a continuous mode. They are not readily modulated

except by external mechanics. The failure mechanism

of lasers is a catastrophic event. Typical replacement

is required every 6–8 months. Replacement costs are

a function of the wavelength generated and can range

from a few hundred dollars to $10,000, resulting

in high annual maintenance costs. Serious safety

concerns exist about their use by inexperienced

users and in nontraditional testing environments.

As a consequence of the aforementioned shortcomings,

competition from improved light

sources will likely come from diode lasers and

LEDs. Significant improvements in these semiconductor

products have already resulted in

enhanced brightness, increased wavelength range,

and cost reductions. However, diode lasers are primarily

targeted for telecommunications and do not

readily provide wavelengths in the visible and UV

ranges of the spectrum, those required for bioanalyses.

Techniques typically employed to generate

these wavelengths, including frequency doubling,

are unlikely to be employed for low-cost light engine

designs. Difficulties with beam shape, power stability,

and reliability are other issues yet to be resolved.

One exception receiving significant attention in

newer instrument applications is the up-converted

IR diode laser, the so-called diode pumped solid-state laser (DPSS). These lasers are less expensive, more

powerful, and longer-lived than their predecessors.

However, they too demonstrate certain limitations,

namely, a limited number of emission lines and the

need for external modulation, and they remain prohibitively

expensive for many applications.

LEDs

LEDs are now available in a relatively wide range of

wavelengths. However, their output is significantly

broad so as to require filtering to achieve usable bandwidths

on the order of 10–30 nm. Additionally, output

in the visible spectrum is profoundly reduced in

the yellow and green. This gap in usable wavelength

range compromises their utility for bioanalyses where

multicolor excitation throughout the visible spectrum

is required. In many life science applications, sufficient

light intensity cannot be obtained from individual

LEDs, or from arrays of LEDs. Designs based on

LED arrays lead to uniformity, stability, and durability

issues. The spatially broad output results in lower collection

efficiencies and contrast ratios. Their main

advantage, low unit cost, is often offset by the cost

and complexity resulting from additional components

required for their implementation.

Light engines based on light pipes

Most important in the above discussion of traditional

light technologies is that they cannot be readily

improved for bioanalytical applications. The associated

light engine market does not justify the investment

necessary to overcome fundamental performance limitations. As a result, in today’s environment, analytical

instrument performance and price are constrained by

the light source. Moreover, the numerous manufacturers

of lamps and lasers provide only a light source, not

an integrated light engine. The Lumencor light engine

is designed to provide a well-integrated, cost-effective

subsystem that simplifies light subsystem implementation

and does so with enhanced performance.

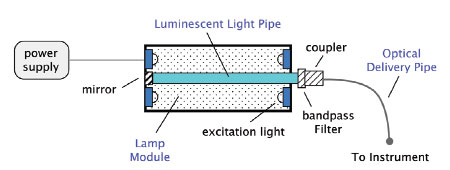

Light engines are light delivery subsystems that consist

of a light source and delivery optics. A schematic

is shown in Figure 2. Light is generated by exciting

luminescence in a rod or light pipe, which may be

driven by an e-beam, LEDs, or UV bulbs. The light

pipe geometry integrates a significant fraction of the

light, resulting in high external efficiencies. Efficiency

is optimized by the design of the lamp module, including

the excitation source and the geometric shape of

the pipe. Increased power and intensity are obtained

by scaling the light pipe and associated excitation.

Figure 2 - Schematic of a single-color light engine.

The pipe, which consists of any of a variety of luminescent

materials (e.g., rare earth doped glass, organic

doped plastic, doped single-crystal fiber), is tailored

to emit light in the UV through the IR range. In

the case of the rare earths, emission is inherently

narrow due to their atomic-like energy structure.

Unwanted light is removed with a bandpass filter.

The light output from the luminescent pipe is fed

into an optical delivery pipe and directed into the

analysis instrument or tool. Fast luminescence decay

results in rapid switching, with no appreciable warmup

time for these long-lived, durable materials.3

Each color produced within a light engine requires a

unique combination of light pipe and excitation source.

Moreover, each application requires one of several different

approaches to coupling light from the delivery

pipe into sample volumes. As an example, the light in

a Sanger sequencer is coupled to a row of 50-μm-i.d.

capillaries. Quantitative PCR (Q-PCR) tools typically

require uniform excitation in an array of wells within

a multiple-well plate with no illumination of the interstitial

spaces. Fluorescence microscopes need uniform

light piped through the objective. Microfluidic chips

employ unique detection capillaries and/or flood illumination

of a plurality of channels, spots, or wells. To

satisfy the range of instrument architectures, imaging

and nonimaging optics are utilized.

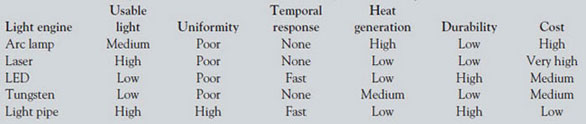

While no one lighting solution can best satisfy every

instrument architecture, light pipes meet or outperform

the traditional technologies listed in Table 1

on the basis of all figures of merit for all individual

wavelengths. Single outputs, such as red from a diode

laser, may be competitive. However, no family of

outputs can be assembled that bests the pricing of

the light engines described here. As an example, a

Lumencor light engine can emit narrowband light

exceeding 500 mW/color with intensities above 100

W/cm2. Bandwidths as narrow as 10 nm are achievable.

While such output power and overall emission

intensity are impressive, the most significant figure of

merit for quantifying the value of any lighting subsystem

for bioanalytics is the intensity of high-quality

illumination provided to the sample. This is dictated

by the instrument design and sample volume and

is clearly very application specific, e.g., fluorescent

microscopy for live cell imaging vs for reading a chip

designed for gene expression analysis.

Table 1 - General comparison of various sources used in light engines for bioanalyses

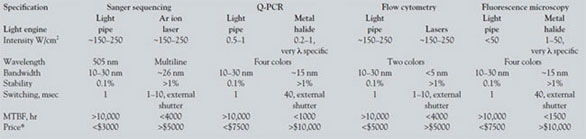

A more detailed comparison of present-day light

engines employed in a number of bioanalytical

instruments with that of a light engine based on light

pipes is shown in Table 2. Significantly, the relevant

comparison is among proprietary lighting subsystems,

not published specifications for a particular

light source. Here, the most important figure of merit

is intensity. The amount of fluorescent signal generated

for a given analyte in each tool is defined by

the S/N of the instrument. This ratio is optimized by

maximizing the number of photons into the analysis

volume and therefore by the illumination intensity

delivered to the analyte in mW/cm2 with the

important caveat that the illumination not degrade

the sample itself. Necessarily, performance is a function

of instrument architecture. Examples include

Sanger sequencers, which use individual argon ion

lasers to simultaneously irradiate an array of up to

96 capillaries (50 μm i.d.) fed electrophoretically

from a multiple-well plate. Tools for Q-PCR most

often require multicolor illumination of high-density

multiple-well plates using mechanical shutters to

switch among wavelengths. Multiplexed chip technologies

and high-density microchannel approaches

are even more demanding in terms of illumination

intensity. Flow cytometry is typically carried out in

serially addressed and spatially separate aliquots of a

continuous flowing, focused stream. Finally, optical microscopes for fluorescence detection require uniform,

stable light, and their intensity requirements

are essentially defined by the objective and the illumination

area under interrogation.

Table 2 - Lumencor light engine output vs light engines based on traditional sources for bioanalytical applications*

Intensity values differ by orders of magnitude. This is

a direct consequence of the instrument architecture

and the corresponding illumination area dictated by

the sample volume. As a result, highly multiplexed

analysis like those performed using microarrays

require very high intensities to satisfy numerous

small illumination volumes. It should also be noted

that intensity values have a wavelength dependence;

this is much less an issue for light pipes. For example,

while it is possible to achieve W/cm2 intensity values

for a band of light centered at 546 nm out of

the metal halide lamp, much lower intensity values

are produced in other colors such as cyan and red.

Similarly, in the case of light engines based on LEDs,

insufficient power is available between 520 and 590

nm. Relatively, light pipes achieve nonwavelength-dependent

emissions due to the plethora of materials

that are available to produce bands throughout

the UV, VIS, and IR regions of the spectrum; not

every band is possible, but as many as eight unique

colors can be produced with comparable intensity

and brightness. It is possible to integrate the luminescence

for long rod lengths, yielding high emissions.

Finally, because these bands are produced by

individual emitters designed within independently

controllable subunits, light engines have unique

temporal and spatial properties that should enable

new instrument designs and capabilities. Each color

is uniquely operable such that modulation between

colors and simultaneous irradiation by multiple colors

is possible. These light engines make it feasible to

provide controlled excitation for multiplexed analyses

with no external mechanics, filters, or shutters.

Exploitation of this solution for life science applications

promises to enable highly multiplexed analyses

in the next generation of low-cost, portable, high-density

instrument platforms.

References

- Lee, G.; Chu, K.; Conray, L.; Fix, L.; Lui, G.; Truesdell, C. Optik & Photonik June 2007, 2, 30–5.

- www.exfo-xcite.com.

- Bioanalytical instrumentation using a light source subsystem, US-2007-0281322-A1.

Mr. Conner is Vice President, Engineeering; Dr. C. Jaffe is

Vice President, Business Development; and Dr. S. Jaffe is

President, Chief Executive Officer, Lumencor, Inc., 15455

NW Greenbrier Pkwy., Ste. 210, Beaverton, OR 97006,

U.S.A.; tel.: 503-530-1008; fax: 503-536-6741; e-mail:

[email protected].